At CAD-IT Australia, we believe that implementing leading technology can make an incredible difference in your business and its operations.

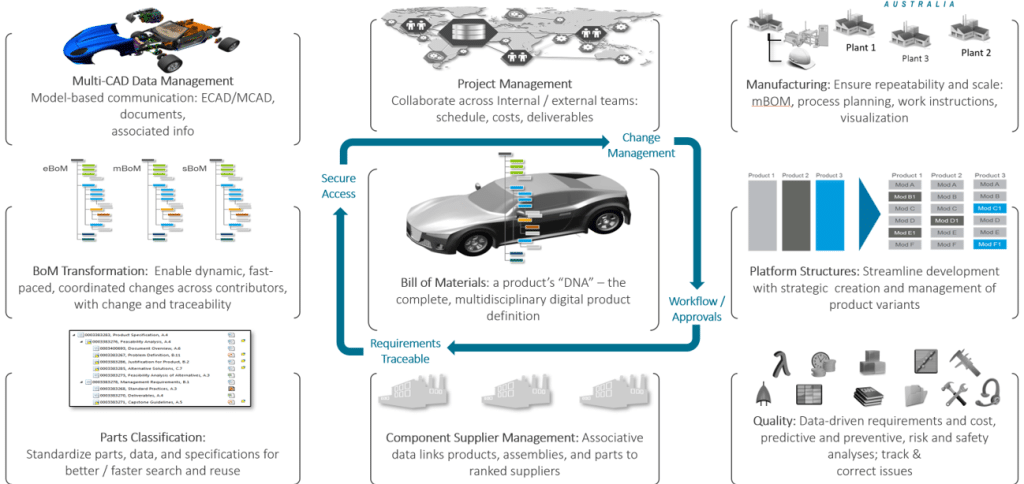

Windchill is a product lifecycle management software designed to allow easy integration with other enterprise systems including IoT, providing strong grounds for a product driven digital thread. Windchill allows multidisciplinary teams to work together and access data securely without any geographical limitations all whilst delivering quality-focused processes through a data driven approach to manufacturing.

With the application of the PLM software Windchill, you can expect:

Windchill offers user experience ranging from expert to inexperienced. In 2D, 3D, and augmented reality forms, this PLM software allows users to see, markup, interact with, and collaborate on various types of digital product data. Windchill will assist with the following in product lifecycle management:

Windchill’s capabilities include but are not limited to the following;

Windchill can be used by non-experts who don’t use PLM frequently. This software will help the growth of your business on-premises and in-cloud. Below are the suites on offer to assist with your product lifecycle management.

With over 20 years experience in the manufacturing industry, our team of experts are here to support you, challenge your ideas and provide you with an outsider’s point of view. We believe in doing things differently and that there is always room for improvement. We are dedicated to the successful implementation of systems within your organisation so that you have an improved schedule for achieving tasks. So what are you waiting for? Talk to a specialist today.

Vaillant Group is taking a long-term approach to their digital transformation driven by Product Lifecycle Management (PLM).

Maker of turbochargers for ship diesel engines installs PTC’s Product Lifecycle Management (PLM) solution for business-process standardization and BOM-centric PLM.

Bringing together Engineering, Supply Chain, and Manufacturing through the Digital Thread

Transforming processes to minimise costs and improve efficiency whilst maintaining ISO standards