With retiring experts and global workforce disruptions causing turnover, companies are met with unmet skill gaps and lengthy upskilling times for new hires. Digital work instructions provide the correct information with visual indicators for new hires to onboard quickly.

As supply chain shortages and shifting priorities impact businesses around the globe, companies need to constantly update production lines to meet deliveries. Introducing new products and shifting priorities with no-code apps enables quick changeovers to keep production running smoothly and consistently meet deliveries

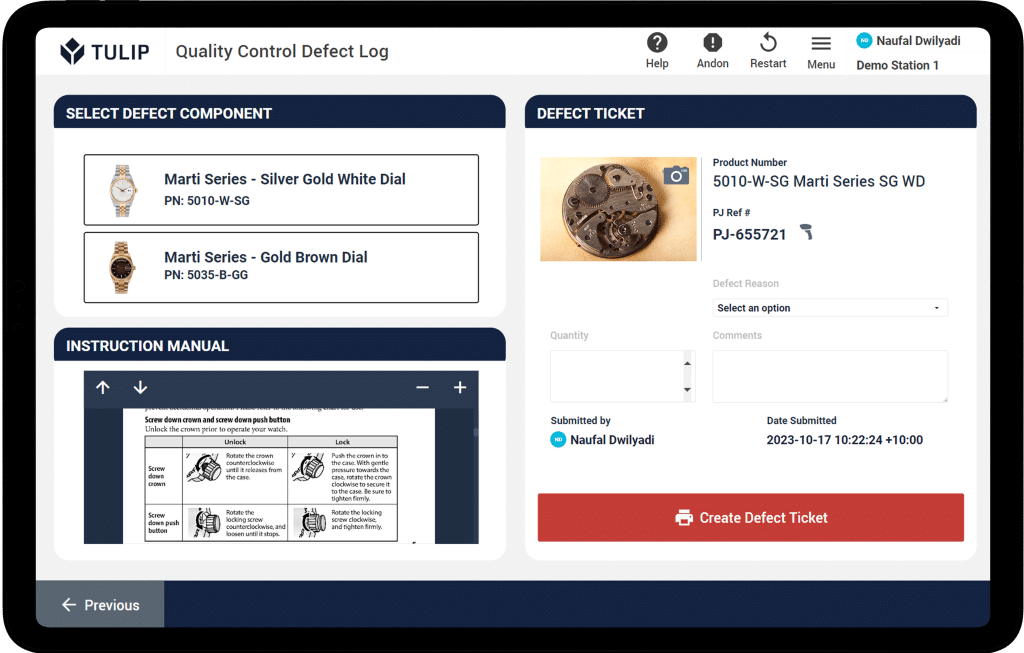

Product variations and defects from out-of-spec parts lead to rework and create waste while damaging customer trust. Ensuring quality upstream with traceability and complete product visibility reduces customer complaints and increases completed orders.

CAD-IT Australia provides tailored solutions for the retail and consumer industry. Leveraging Tulip Interfaces for digital work instructions, our services optimize shop-floor operations, ensuring efficiency and real-time process guidance. Integrating Thingworx Industrial IoT enhances data-driven decision-making, from supply chain to inventory management. Our expertise empowers retailers to navigate skilled worker shortages, consumer demand fluctuations, and cost pressures, fostering a resilient and agile business model in the dynamic retail landscape.

Vaillant Group is taking a long-term approach to their digital transformation driven by Product Lifecycle Management (PLM).

The Griffin’s Food Company focuses on speed and scale to achieve digital transformation.

PTC’s ThingWorx Unlocks Real-time Performance Monitoring and Predictive Maintenance Across Brewing Facilities

Laerdal Medical built a unique and powerful solution with Tulip vision to ensure all parts of assembled kits are complete before shipping to customer sites.